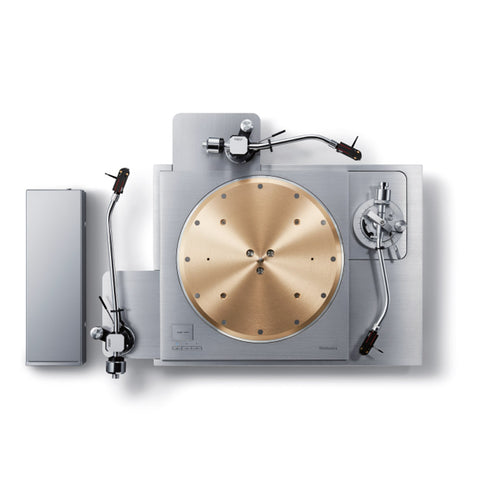

Technics SP-10RS Reference Class Direct Drive Turntable

Coreless Direct Drive Motor

The motor that forms the heart of the direct drive turntable is based on the coreless direct drive motor that was developed for the SL-1200G launched in 2016, and further improved. The double coil twin rotor-type coreless direct drive motor that was newly developed for this purpose had coils on both sides for 12-pole, 18-coil drive, with high enough torque to drive the heavyweight-class platter (approximately 7.9-kg). Offsetting the coils on both sides 60 degrees improved the rigidity of the substrate, suppressing fine vibrations and reducing self-inductance. These improvements achieved stable rotation of 0.015% wow and flutter or less, which is considered to be the measurement limit. Also, the thrust bearings supporting the heavyweight-class platter use a special engineering plastic to provide both high rigidity and reliability.

Suppressing Unwanted Motor Vibration

The motor that was developed for the SL-1200G served as the platform for the direct drive motor. The double coil, reinforced thrust bearings, and a chassis with increased rigidity achieved a stabilised motor with low centre of gravity. By positioning two stainless steel weights with high rigidity and high specific gravity at the bottom of the chassis, the rigidity and low centre of gravity are maintained. These thorough measures to prevent unwanted vibration help to achieve overwhelming rotary precision and improve S/N.

Heavyweight-class Turntable Platter

The turntable platter positions tungsten weights, which have an extremely high specific weight and are difficult to process, on the outer periphery of a 10-mm-thick brass weight. The brass weight is laminated onto the aluminium die-cast, giving the platter a total weight of approximately 7.9 kg and an inertial mass of approximately 1 ton・cm. A deadening rubber for eliminating unwanted vibration is also attached to the rear surface to form a 3-layer construction and achieve high rigidity and excellent vibration damping characteristics.

Separate Control Unit

The control unit is separated from the main unit to suppress the effects of unwanted noise on the main unit. In order to achieve a power supply circuit that provides good regulation for high torque, a switching power supply is used. To reduce the noise reaching the pickup, the switching power supply is equipped with a unique technology that provides a voltage supply with minimal noise by a newly developed "unwanted noise reduction circuit". Also, to minimise the noise even during communication, a highly reliable system that resists the effects of external noise is used for communication between the main unit and the control unit. These thorough noise-reduction measures achieve the world's highest-level S/N.

Minute Adjustment and Indication of Rotations

This turntable supports not only LP (33 1/3 rpm) and EP (45 rpm) analogue records, but also SP (78 rpm). Rotation (rpm) can also be set down to two decimal places (maximum ±16%) from the control unit. The OLED display is also capable of displaying rotation with accuracy down to two decimal places, so the user can both hear and see extremely precise rotation.

SP-10MK2 and SP-10MK3 Compatibility

In order to enable users to continue using the turntable base and tonearm of systems including the SP-10MK2 and SP-10MK3, the shape and screw positions of the SP-10R base plate are designed to allow mounting onto the SP-10MK2 and SP-10MK3 for complete backward compatibility. The control unit is also the same shape and size as the SP-10MK2 power unit for trouble-free replacement.

FREE SHIPPING OVER $199

FREE SHIPPING OVER $199