Yamaha NS-5000 Speakers

$21,999.95

Pay as per month with Affirm

Product Details

Add to shopping cart is not available for some Yamaha Products, Please call or email us to place your orders.

Yamaha NS-5000 Speakers

| NS-5000 Specifications | |

| Type | 3-way bookshelf, bass-reflex system |

| Frequency response | 26 Hz - 40 kHz (-10 dB), - 100 kHz (-30 dB) |

| Normal input power | 200 W |

| Maximum input power | 600 W |

| Sensitivity | 88 dB / 2.83 V / 1 m |

| Nominal Impedance | 6 Ω (minimum 3.5 Ω) |

| Crossover frequencies | 750 Hz, 4.5 kHz |

| Diaphragm | ZYLON® |

| Voice coil | Square copper wire |

| Tweeter | 3 cm, ferrite, non-magnetically shielded |

| Midrange | 8 cm, ferrite, non-magnetically shielded |

| Woofer | 30 cm, ferrite, non-magnetically shielded |

| Filter characteristics | Tweeter: -18 dB / oct. |

| Midrange: -12 dB / oct. (low), -6 dB / oct. (high) | |

| Woofer: -6 dB / oct. | |

| Input | Single |

| Dimensions (W x H x D) | 395 × 690 × 381 mm |

| 395 × 690 × 422 mm (including speaker terminals) | |

| 15-1/2” x 27-1/8” x 15” | |

| 15-1/2” x 27-1/8” x 16-5/8” (including speaker terminals) | |

| Weight | 35 kg; 77.2 lbs. |

| Accessories | Separate protectors (for tweeter, midrange and woofer), port plug, owner’s manual |

| * Speaker cables are not included. | |

Speaker Units

Newly developed diaphragms boast acoustic velocity comparable to that of beryllium

NS-5000's tweeter, midrange, and woofer all feature diaphragms made of 100%*1 ZYLON® — a synthetic fiber created in Japan rated as the world’s strongest*2 and boasting optimum elasticity — using Yamaha’s original monel alloy vapor coating deposition method. The soft-dome diaphragm suppresses peaks and dips in the frequency response caused by the inherent resonance of the diaphragm, while taking advantage of ZYLON®'s high acoustic velocity comparable to that of beryllium, considered as the ideal diaphragm material for its hardness, lightweight (low density), and stiffness. The result is a remarkably flat frequency response, with unified tone color and acoustic velocity over the entire frequency range, providing comfortable listening experience and meticulously accurate, superb sound reproduction of the highest degree.

*1 Using 100% for the base material.

*2 Comparative data concerning all existing organic fibers (source: Toyobo Co., Ltd., May 2015)

Newly developed R.S. (Resonance Suppression) Chambers suppress unwanted resonance in the mid and high ranges

Mounted on the back of the tweeter and midrange speaker units are newly developed R.S. Chambers (patent pending) that suppress unnecessary tube resonance generated behind the diaphragm. Two specially shaped tubes installed in accordance with our proprietary acoustic analysis cancel tube resonance. These R.S. Chambers achieve higher-resolution audio reproduction by eliminating the need for a large quantity of sound-absorbing material inside the enclosure that tends to smooth the frequency response of each speaker unit and might degrade minute nuances of the sound.

Enclosure

30 cm (12”) 3-way bookshelf design draws on the tradition of the legendary NS-1000M

As a result of meticulous research on a variety of enclosure designs during the development of the NS-5000, we chose a bookshelf design as a successor to the continuing legacy of the NS-1000M (released in 1974), the pinnacle of Yamaha monitor speakers. This bass-reflex enclosure with an internal volume of 65 liters — the smallest possible size for a 30 cm (12”) 3-way configuration — is solidly assembled with the 3-way mitered joint construction technique and other traditional crafting methods. Reinforcing crosspieces inside the enclosure, based on FEM analysis, suppress “box ringing” caused by delayed vibration from the six surfaces of the enclosure. In addition, a twisted flare port prevents port noise (wind noise produced at each end of a bass reflex port) inherent in the bass reflex design, and improves resolution in the low frequency range while also enhancing signal-to-noise performance.

Carefully crafted laminated plywood enclosure made of Japanese white birch from the island of Hokkaido

In selecting a material for the enclosure of the NS-5000, we carried out comprehensive studies of mechanical strength and acoustic properties of various materials, as well as the quality of domestic wood processed by painstakingly removing every knot and hole from the lumber and ensuring the durability necessary to withstand long use; we settled on laminated plywood made of white birch from the island of Hokkaido. Moreover, the birch wood is harvested with ecoforestry techniques, extracting timber from ecologically protective forest thinning, for environmental considerations. The front baffle is 29.5 mm (1-1/8”) thick and the other five sides of the enclosure 20 mm (3/4”) (in all cases, omitting paint primer layer and paint thickness), ensuring ideal rigidity of the entire enclosure.

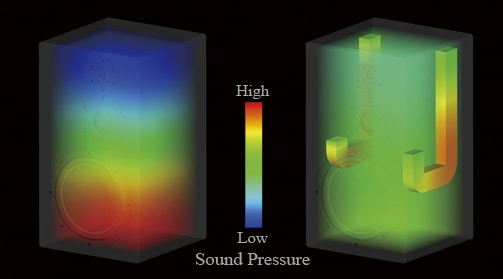

Newly developed Acoustic Absorber eliminates sound-absorbing material to revive the original presence of the music

The cuboid enclosure unifies internal standing waves at a specified frequency, which are cancelled by a newly developed Acoustic Absorber (patent pending). This technology eliminates the previous need for the huge amount of sound-absorbing material inside the enclosure. The result is the virtual elimination of standing waves with amazing efficiency and pin-point accuracy — to energetically revive the essential presence of music, formerly lost by sound absorption.

Glossy black piano finish provides improved signal-to-noise performance — and adds to the luxurious joy of ownership

All six external surfaces of the enclosure have a glossy black piano finish created using the same dedicated paint, primer, and polishing processes used for Yamaha’s renowned grand pianos. The uniform and hard membrane further increases the overall rigidity of the enclosure, and at the same time it suppresses fine vibrations, contributing to the bright sound and significantly enhanced signal-to-noise performance.

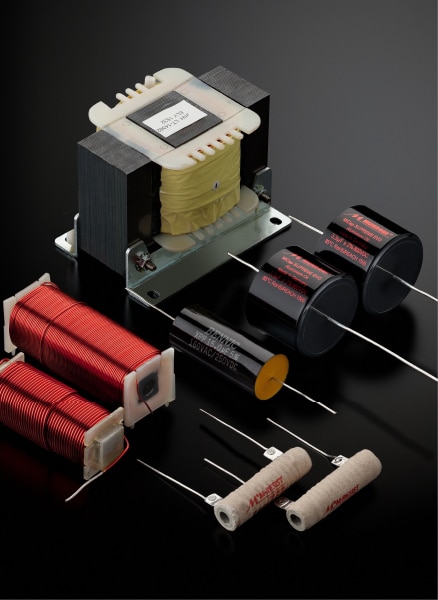

Crossover Network

All drivers in the NS-5000 are connected in positive phase with single wiring to deliver a natural, pleasing listening experience. Components of its crossover network are mounted on a double-sided printed circuit board with extra-thick copper traces of 140 μ in thickness; a shorter signal path on the circuit board minimises the loss of sound data during transmission. Moreover, in order to minimise signal loss, we used for the network handpicked parts of only the highest quality, such as the MCap SUPREME EVO audio capacitor, which is made by Mundorf of Germany and renowned as the pinnacle of audio-use capacitor, Mundorf’s MResist SUPREME attenuator, and a woofer coil that weighs as much as 1.6 kg (3.52 lbs.).

In Hi-Fi speaker systems, fiber, plastic, and metal used for diaphragms have their own inherent acoustic properties, which in turn give distinctive characteristics to drivers as well as to complete speakers. Over the years, relying on speaker engineers' experience and intuition to fine-tune a unique acoustic characteristic derived from a material into an appealing sound coming from a complete speaker has been an established approach to making speakers; this balancing act continued to present an opportunity for speaker engineers to show off their mastery of speaker development.

Departing from conventional wisdom, Yamaha has taken a novel approach to developing the NS-5000 — starting with selecting a diaphragm material. We have chosen textile made of 100% ZYLON® — a synthetic fiber of exceptionally high strength, having acoustic velocity as well as the ability to reproduce the finest details of audio equivalent to those of beryllium but without a sharp resonance peak inherent in a hard material — that has an acoustic characteristic markedly different from that of any other diaphragm material. This rare material presented a perfect opportunity to create a truly ‘Yamaha-esque’ Hi-Fi speaker, fully capable of meeting the demands of the high-resolution era, and reproducing music in greater faithfulness to the original. To this end, Yamaha began in 2008 to develop a speaker diaphragm made of fiber containing 100% ZYLON®. And now, we have a set of three world's first drivers made of 100% ZYLON® — the JA-05K6 3 cm (1-1/4”) soft-dome tweeter, the JA-08B5 8 cm (3-1/4”) soft-dome midrange, and the JA-3132 30 cm (12”) cone woofer.

In particular, the JA-08B5 8 cm (3-1/4”) midrange — one of the world’s largest dome midranges — most closely symbolises the design philosophy of the NS-5000 — which is to realise the full potential of a 100% ZYLON® diaphragm. The driver's dome configuration allows loss-free movement, and its broad directional characteristic reproduces a rich sound field. Moreover, the NS-5000 incorporates three additional innovations: (1) R.S. (Resonance Suppression) Chambers on the tweeter and midrange cancel out tube resonance from the back of the drivers; (2) Acoustic Absorbers eliminate the need for a large quantity of sound-absorbing material that would dampen the acoustic energy produced by the woofer, and ensure more accurate reproduction of the original dynamism in the music; and (3) An enclosure-reinforced structure, crafted with the use of advanced FEM analysis and meticulous laser measurements, effectively suppresses “box ringing.” All these technological innovations combine to achieve non-coloration and exceptionally wide range — made possible only with ZYLON® — with an unprecedented level of noise-free clarity.

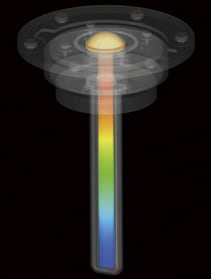

100% ZYLON® 8 cm (3-1/4”) soft-dome midrange — the JA-08B5

The JA-08B5 8 cm (3-1/4”) soft-dome midrange is made of 100% ZYLON®, molded seamlessly from the diaphragm to the surrund (edge) thanks to our proprietary molding technology. The system design of the NS-5000 began with the crafting of this midrange driver. In order to take full advantage of impressive acoustic velocity and realistic acoustic density that the 100% ZYLON® diaphragm provides, we adopted a dome design — which shortens the distance from the voice coil to the diaphragm to a degree impossible with a cone design, resulting in smaller loss of movement — and we made its diameter 8 cm (3-1/4”), which is the largest feasible size that manufacturing yield allows. The high-pass crossover frequency was set at 750 Hz, optimum for bringing out the very best in this driver.

100% ZYLON® 8 cm (3-1/4”) soft-dome midrange

100% ZYLON® 3 cm (1-1/4”) soft dome tweeter – the JA-05K6

Just as with the 8 cm (3-1/4”) mid-range, the JA-05K6 3 cm (1-1/4”) soft-dome tweeter is made of 100% ZYLON®, molded seamlessly from the diaphragm to the surround (edge). Since the woven material for the diaphragm was specially developed for the tweeter, differing from the mid-range in the number of threads and their thickness for the warp and woof, and since the yoke of the magnetic circuit features fully cutting-processed parts (avoiding stress deformities caused by machine pressing) and achieve higher magnetic performance, the system delivers smooth response up to the high-end frequencies, as well as superior S/N performance, high resolution, and increased audio information. The voice coil consists of a square copper wire with sectional shape identical to that of the mid-range and woofer, ensuring maximum efficiency of electro-acoustic conversion, and even finer, more accurate reproduction of audio information through high driver power—as well as achieving reduced transmission loss and lighter weight by directly linking the voice coil to the terminal board instead of another relay wire.

100% ZYLON® 3 cm (1-1/4”) soft-dome tweeter

100% ZYLON® 30 cm (12”) cone woofer—the JA-3132

The JA-3132 30 cm (12”) woofer features a 100% ZYLON® cone without a centre cap. It was designed to offer a wide frequency range unprecedented for a 30 cm (12”) woofer, in order to provide not only a flawless continuity in tone from the woofer to the midrange and to the tweeter as well as acoustic sharpness, both of which was made possible with the use of the identical material for all drivers, but also optimum performance with the higher low-pass crossover frequency of 750 Hz. The woofer's aluminium die-cast frame achieves high rigidity while minimising air resistance at the rear, thanks to the state-of-the-art design based on rigorous FEM analysis of the frame mounted in a prototype enclosure.

100% ZYLON® cone woofer

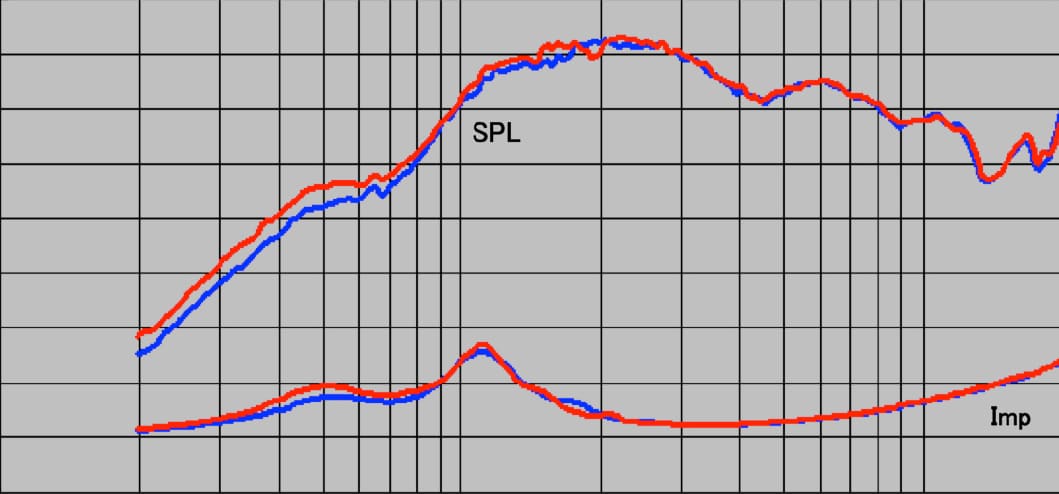

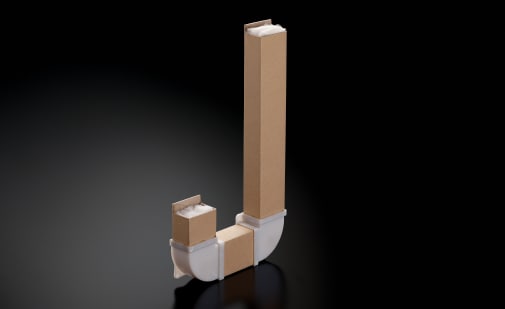

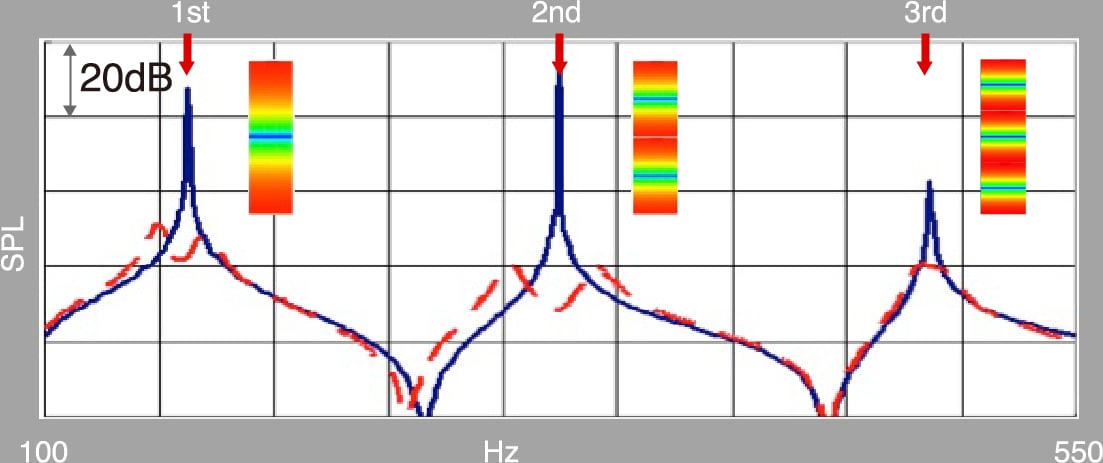

R.S. Chamber

Suppressing unnecessary acoustic radiation from the back surfaces of the tweeter and the midrange has been a challenge to many speaker engineers. They have taken a variety of approaches to addressing the challenge, including adding a small back chamber packed with sound absorbing materials. However, almost all conventional methods required a large amount of sound-absorbing materials to eliminate strong resonance inside the chamber. With the NS-5000, we have taken a radically different approach; we equipped the backs of the 100% ZYLON® 8 cm (3-1/4”) midrange and 3 cm (1-1/4”) tweeter with the newly developed R.S. Chambers (patent pending). Each of the R.S. Chambers uses two resonance tubes of different lengths to cancel out the resonance peak produced in the main chamber in the middle, thus eliminating the need for sound-absorbing materials inside the chamber that would degrade the sound. The result is that each driver can retain its native flat frequency characteristics and that delicate nuances of music can be reproduced with exceptional detail and articulation.

Straight tube

R.S. Chamber

- Frequency characteristics of R.S. Chamber

- Straight tube filled with sound-absorbing materials

Acoustic Absorber

Applying know-how obtained in the development of acoustic conditioning panels, we developed an Acoustic Absorber (patent pending) — a compact J-shaped resonance tube that eliminates standing wave of a specific frequency — and installed two of them in the NS-5000. The speaker's uncomplicated cuboid enclosure helps consolidate internal standing waves at a specific frequency and makes it easy for the Acoustic Absorber to target and suppress that frequency. This eliminates the need for a large amount of sound-absorbing materials inside the enclosure, and helps bring the natural acoustic resonance out of the original music. Acoustic Absorbers also ensure a remarkable continuity in tone between the woofer and the midrange, ensuring that, unlike in a conventional enclosure filled with a substantial amount of sound-absorbing materials, much of the acoustic energy in the high frequency range generated by the woofer is kept intact.

Acoustic Absorber

See-through view of two Acoustic Absorbers installed in the enclosure

Acoustic Absorber in action

![]() Without Acoustic Absorber

Without Acoustic Absorber ![]() With Acoustic Absorber

With Acoustic Absorber

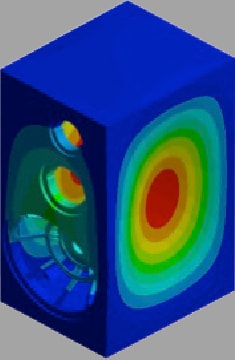

Groundbreaking enclosure design

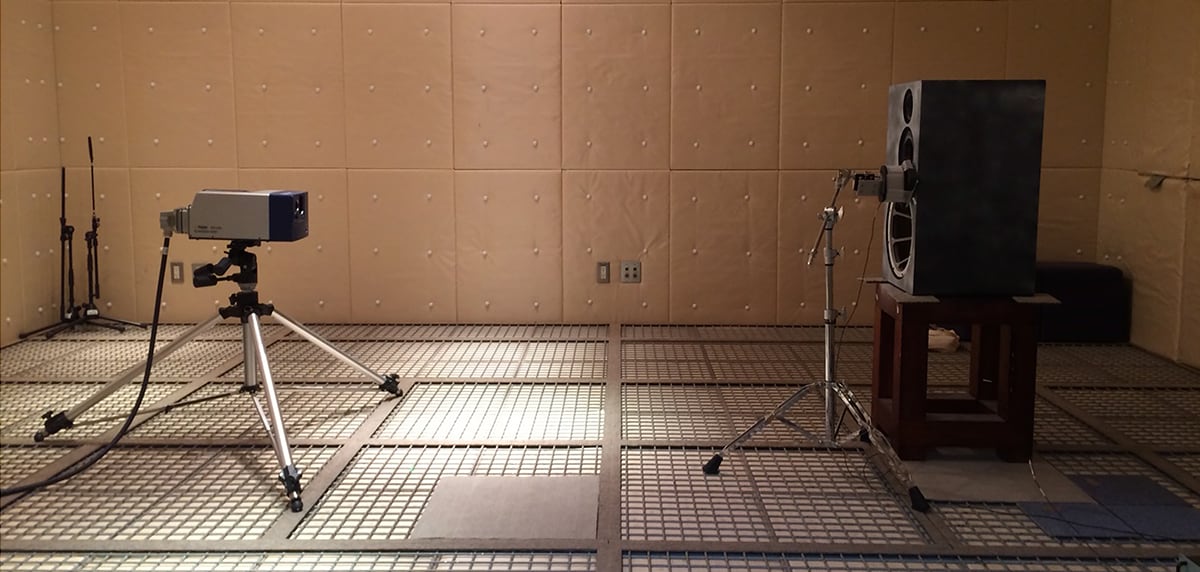

Aided by laser-scanning measurement and state-of-the-art FEM analysis, we developed a unique enclosure structure that effectively controls “box ringing” to a degree undetectable by human ears. Inside the enclosure, we installed proprietary reinforcing bars designed by simulating with pinpoint precision the way sound from the speaker units is transmitted to and emitted from the six surfaces of the enclosure. These reinforcing bars play an important role in perfectly synchronising the timing of acoustic resonances generated by the enclosure, which helps reproduce the natural acoustic vibrancy with amazing purity and clarity — offering a listener with an unprecedented level of immersive audio experience.

FEM analysis

Determining the vibration mode of the enclosure’s surfaces with a laser measuring device

FREE SHIPPING OVER $199

FREE SHIPPING OVER $199